Selection of sandblasting equipment

1. Generally speaking, the effect of sand blasting is mainly determined by parts materials and abrasive blasting. According to the different parts of the material, abrasive blasting range can be from the effect of strong metal abrasive to the effect of soft resin abrasive, while dry sand blasting and liquid sand blasting is also the key factor to consider.

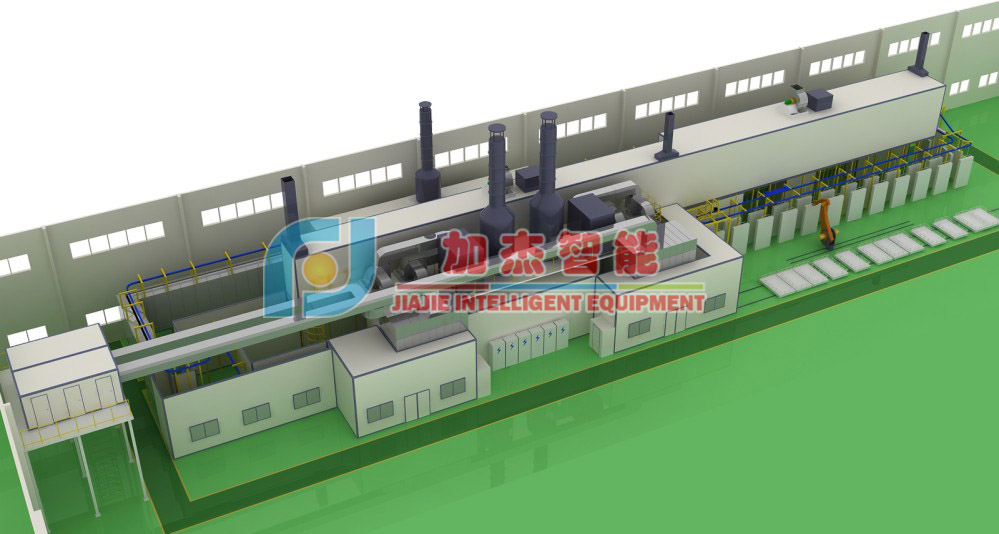

2, production efficiency to determine the type of equipment. Select automatic sandblasting production line, semi-automatic sandblasting equipment, press-in sandblasting machine, suction sandblasting machine according to the processing capacity.

3, the workpiece size to determine the equipment specifications. Select engine room size according to workpiece size so that there is enough space for processing.

4. Compressed air requirements. Determine the capacity of air compressor according to equipment specifications, and leave a margin of 20% to protect the service life of air compressor.

Function or purpose

1. Cleaning the surface of the workpiece

Available against the corrosion of the metal layer, on the surface of the heat treatment of residual salt and oxide layer and oxide layer on the surface of the rolled piece, oxide layer on the surface of the forging parts, welding parts, casting surface oxide layer on the surface of the sand and the residual dirt on the surface of the oxide layer, and the tiny burrs, surface processing, such as the old part to remove the surface layer, show matrix ecru, cleaning the surface quality can achieve Sa3 level.

2. Pretreatment of the workpiece surface before coating

It can be used as pretreatment of various electroplating processes, brush plating processes, spraying processes and bonding processes to obtain active surfaces and improve adhesion between coatings, coatings and bonding parts.

3. Change the physical and mechanical properties of the workpiece

It can change the surface stress state of the workpiece, improve the lubrication condition of the mating part and reduce the noise during the coupling movement. Can make the workpiece surface hardening, improve the wear resistance and fatigue strength of the parts.

4, the surface of the workpiece finish processing

Ra value of workpiece surface roughness can be changed. A surface that can produce matte or diffuse reflection for finishing purposes.

Ii. Main parameters

The main parameters affecting the sandblasting process are abrasive type, abrasive particle size, abrasive concentration, jet distance, jet Angle, jet time, compressed air pressure and so on.

Iii. Environmental protection features

1. Greatly improved the environmental pollution caused by dust and the harm to workers' health;

2, can be directly installed in the production line, save production area, conducive to the turnover of the workpiece;

3. Flexible working method, variable process parameters, able to adapt to different materials and different precision parts of the lighting processing requirements;

4. The abrasive is recycled in the working process, and the consumption is small;

5. Main parts have long service life and are easy to maintain.

Technological parameters of sand blasting are commonly used

Three elements to obtain surface results:

Acceleration of jet flow by compressed air (adjustment of sandblast pressure) P

Type of abrasive (S)

Distance (H), Angle () of the spray gun

1. Influence of pressure adjustment on surface results

After S, H, and are set, the higher P value is, the higher jet flow velocity is, the higher sand-blasting efficiency is, and the rougher the surface of the processed workpiece is. On the contrary, the surface is relatively smooth.

2. The influence of distance and Angle of the spray gun on the surface results

After P and S values are set, this is the key of manual sandblasting technology. The distance between the gun and the workpiece is generally 50-150mm. The farther the gun is from the workpiece, the lower the efficiency of the jet flow and the smoother the surface of the workpiece. The smaller the Angle between the gun and the workpiece, the lower the efficiency of the jet flow and the smoother the workpiece surface.

3. Influence of abrasive type on surface results

Abrasive according to the particle state is divided into spherical, diamond two types, sand blasting usually used emery (white corundum, brown corundum) diamond abrasive. The glass beads are spherical abrasive. In P, H, theta three value Settings, spherical abrasive blasting by the results of a smooth surface, the diamond abrasive surface are relatively rough, but the same kind of abrasive and thickness, according to the number of mesh division domestic abrasive degree of thickness, generally called the number, the higher the number, and the smaller the particle size, P, H, theta value set, the higher the serial number of the same kind of abrasive blasting, the surface of the obtained result is more smooth.

客戶服務(wù)熱線

客戶服務(wù)熱線